News

- X.J.Group’S enterprise culture

- Successful Strategies of X.J. Group

- 110th canton fair --X.J.GROUP

- New painting production line

- Enameled Coating Pan

Factory profile

Recommendation

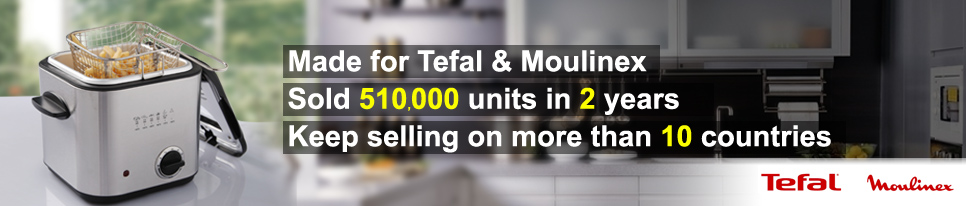

- An introduction of newest deep fryer---XJ-10302

- Which deep fryer do you like?

- An ideal gift -- steam cooker

- Guide of selecting electric pizza maker

- New products of X.J.Appliances

FAQ

Modernized production line

We have 30 modernized new production lines running day and night. These production lines are equipped with wide LCD display and sufficient assistant equipments. By using these LCD monitors, each worker will be guided by clear workmanship & production instructions instead of pasting a paper instruction sheet. Each line is controlled by computer and the files on display can be changed conveniently.

Moreover, all production workshops are equipped with air-conditions, which is quite important in Southern cities in

Subsidiary production line:

We also established assistant production lines such as PCB assembly, power cord assembly, welding, painting & spray and other accessories’ production. The components and accessories can be sent to main production lines for final assembly continuously. By doing so, we can ensure final assembly going smoothly and do not need to rely on other suppliers’ delivery date.

As to the injection, for one shift, we could produce 3,000PCs

Regarding mould tooling, owning a sufficient machinery and manpower, we can finish a mould within 30 days, which ranks one of the best among suppliers.

With complete production facilities, now we produce more than 80% components of a complete unit such as plastic housing, S/S housing, lid, handle, button, etc. Take a stainless deep fryer for example, the S/S housing, bottom cover, heating unit, frying basket, tank and some other accessories are all produced by ourselves. We only need to purchase electronic components, packing materials, cable & power cord from other suppliers.

For moulding, injection, hardware, heating element production, we all produce by ourselves so that the delivery date is controlled precisely and don’t need to rely on other suppliers’ delivery date. Thus all production processes & delivery are controlled efficiently and X.J. could control the final delivery of orders for clients.

As to the daily output, take deep fryer for example, normally it is around 4,000 units per day and 120,000 units per month base don 1 production line. Based on total 30 production lines, X.J. could supply 3,000,000 units per day easily.

With 21 years’ development, X.J. has exported large quantity of products annually and has become one of largest manufacturers for electrical appliances in